Major Sellafield process plant

Under the Programme and Project Partners (PPP) framework, a major project is underway on Sellafield site to construct a new process plant for treatment of nuclear materials. The project is key to Sellafield Limited’s goal of mitigating the risks associated with the long term storage of nuclear materials.

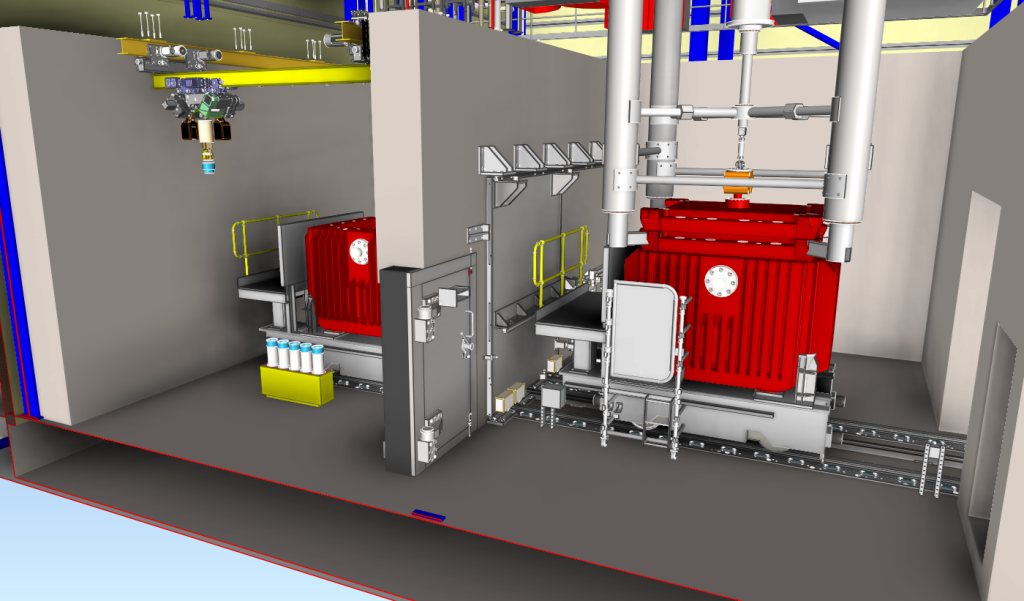

At Tenet’s start point on the project, the process line equipment was approaching the end of the manufacturing stage, and was about to go into Factory Acceptance Testing (FAT) followed by Integrated Works Testing (IWT). The equipment to be tested consists of glovebox lines used for emptying existing containers and repackaging the contents, complete with separate container handling equipment located outside the glovebox containment. The equipment was manufactured by a number of different companies and came together for the first time at the IWT facility.

The equipment installed for IWT includes mechanical and CE&I items, plus process and service items and supplies. The IWT facility was also required to house office space, welfare facilities and laydown areas for use by Sellafield’s commissioning team for the duration of the IWT.

Tenet Consultants were engaged to act as the integrator for the IWT activities, collating information from the PPP design team and equipment manufacturers in order to supply documentation packages to the IWT contractors to enable them to install, assemble and integrate the equipment ready for handover to Sellafield’s commissioning team, who then undertook the IWT.

As the IWT work progressed, Tenet Consultants were also awarded additional scope to provide engineering resource to the project to undertake deferred and emerging tasks, the completion of which was integral to the IWT and eventual site installation.

The IWT replicated the site conditions closely, therefore the work undertaken by Tenet Consultants to facilitate the installation for IWT ultimately benefited the end client when the equipment came to be installed in the process building on Sellafield site.

To meet the requirements of the project, Tenet Engineers have used their vast experience and skill sets, to progress the following technical areas:

Mechanical Activities

- Independent review of PPP design team produced site-specific documentation such as installation method statements, to extract the information necessary to produce IWT facility specific documentation and instructions

- Production of instruction packs to be used by the IWT contractor for installation and integration

- Production of equipment general arrangement drawings, to be used both at the IWT facility and subsequently for final site installation, using the project’s Autodesk Inventor and Vault systems

- Independent review of PPP supplied information to identify shortfalls in information which would hinder or stop the IWT contractor in their installation and integration activities

- When requested by PPP, undertaking the mechanical design activities required to address the shortfalls

- Review of multiple sources of information in order to perform detailed tolerance stack-up reviews of large assemblies of mechanical equipment, to inform IWT facility layout and also the process plant building design on site

- Mechanical design of dedicated IWT equipment, duplicating the function of dedicated site equipment

Liaison between design team, manufacturers and IWT contractors

- Answering queries from IWT contractors

- Review of project documentation with PPP design team to ensure design intent was documented, understood, and replicated in IWT specific documentation

- Visits to manufacturers to obtain information on packaging, handling, lifting etc.

Associated project deliverables include:

- General arrangement and detail drawings

- IWT specific Outline Installation Method Statements

- Documentation to capture design intent for both site and IWT installation

Joining the project at a critical time of its lifecycle, Tenet negotiated a steep project learning curve in a short period of time, hitting the ground running, to provide a seamless extension to our clients engineering capabilities, whilst building and maintaining relationships with our client’s engineers and vendors both in person and remotely across the Microsoft Teams platform.

At Tenet’s start point, the manufacture of the process line equipment was approaching completion and the IWT facility owners required information in a timely manner so that the equipment could be installed in the IWT facility without impacting the project programme.

Tenet’s provided Mechanical resources meet client requirements, using Suitably Qualified and Experienced persons (SQEP) to ensure accuracy, efficiency, safety and integrity of designs and information.

By engaging Tenet, the client was provided with the compliant information packages and design deliverables required to meet the goals of delivering an integrated process line to Sellafield Commissioning for IWT.

Tenet generated, collated, and delivered the information required for the assembly, installation and integration of the process equipment to enable Integrated Works Testing, whilst building and maintaining strong working relationships with our client and their subcontractors.

Tenet provided additional value to our client by undertaking independent reviews of project produced documents, identifying areas where additional information was required in order to successfully compile the IWT installation, and carrying out the engineering tasks required to complete the information packs.

The work undertaken by Tenet for IWT ultimately facilitated site installation by ensuring that the handling, assembly, installation and integration instructions contained all the required information to set up the equipment safely and efficiently.